Euros

Modular shock freezer for 2 or more trolleys

Shock freezer for trolleys designed for medium and large productions. Available in several sizes depending on the quantity, quality and shape of the product to freeze.

Tunnel structure

Equipped with rear door for trolleys exit, ideal for large industrial production in continuous cycle.

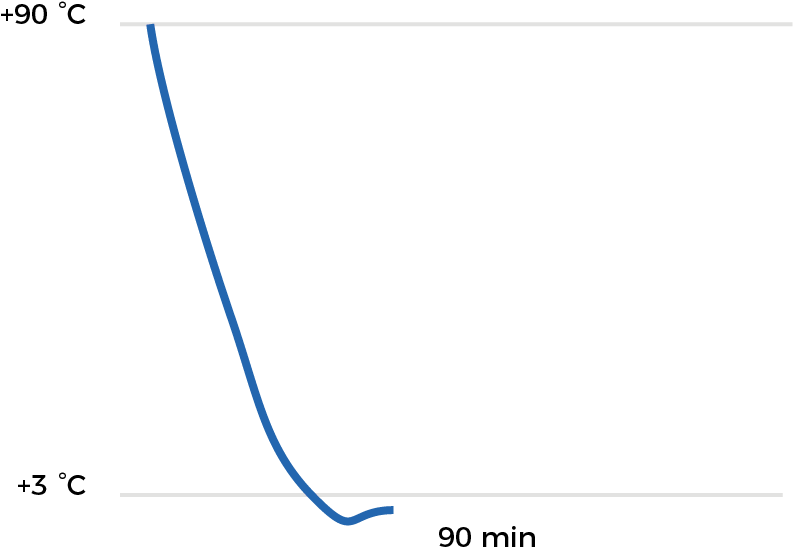

Rapid cooling

The wall of large evaporators along all the freezer depth allows Euros to quickly reach a uniform temperature of -40°C in the whole cabinet.

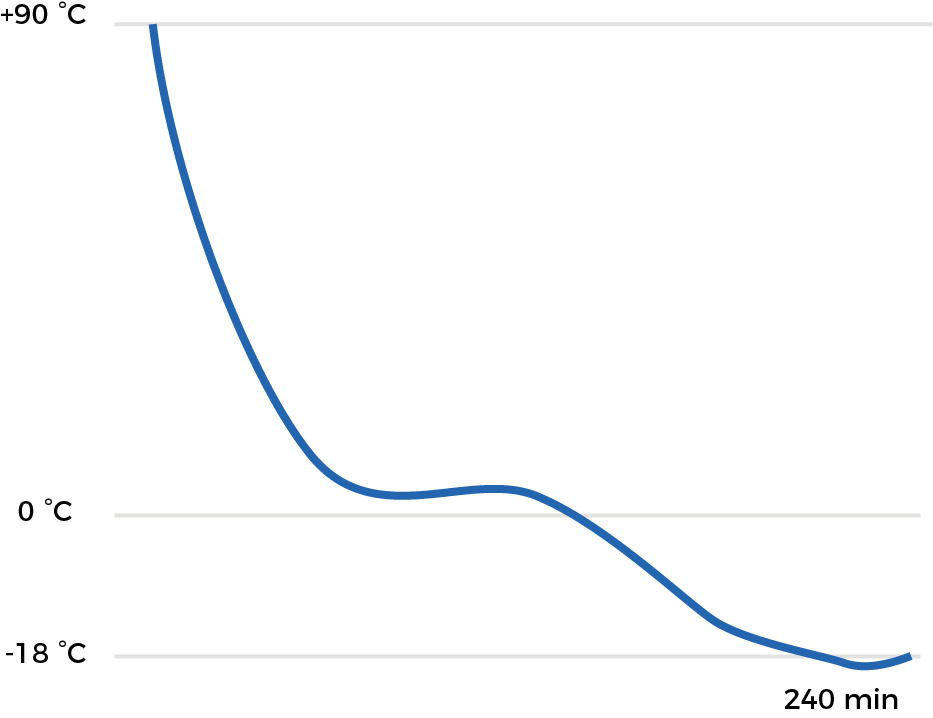

Blast Chilling / Shock Freezing advantages

Quickly lowering the temperature of food is a fundamental process for preserving the organoleptic qualities of food for a long time. The rapid cooling of food guarantees the following advantages:

Prevent bacteria proliferation

The temperature range between +65 °C and + 10 °C where the highest bacteria activity can be observed is quickly passed through, thus minimizing proliferation

Preserves food inner structure

In the shock freezing process the water contained in the foods quickly freezes into micro-crystals which do not tear up the inner structure, as a slower process with macro-crystals formation would

Operating modes

By time

Blast chilling / Shock freezing for a set time duration

With core probe

Blast chilling / Shock freezing until the probe at the product core measures the desired temperature

7” touch screen control panel for Industry 4.0

Equipped with SURG-TOUCH software with:

- Pre-defined Blast Chilling / Shock Freezing cycles

- Work cycle by time or by temperature with core probe

- HARD and SOFT work cycles for blast chilling and shock freezing

- Up to 40 customizable programs

- Automatic switch to storage mode at the end of the cycle

- HACCP log, also available for USB download

- Interconnection with external software or web platform

7” touch screen control panel for Industry 4.0

Equipped with SURG-TOUCH software with:

- Pre-defined Blast Chilling / Shock Freezing cycles

- Work cycle by time or by temperature with core probe

- Modalità HARD per grandi pezzature o SOFT per prodotti delicati

- Up to 40 customizable programs

- Automatic switch to storage mode at the end of the cycle

- HACCP log, also available for USB download

- Interconnection with external software or web platform

Alaska trademark robustness

- 100 mm eco-friendly polyurethane insulation

- Carriageable floor 100 mm with stainless steel finish

- Internal finish in stainless steel

- External finish in either white zinc-plasticized or stainless steel

Available models

Find the Euros model that best suits your productive process based on

- Hourly production rate (kg/h)

- Number and type of trolleys

Technical data

| Model | Blast chilling production +90/+3°C [kg/h] (*) | Shock freezing production +25/-18°C [kg/h] (*) | Capacity of trolleys for trays 60x80 cm [n] | Capacity of trolleys for trays 80x80 cm [n] | Capacity of trolleys for trays 80x100 cm [n] | Internal width Li [cm] | Internal depth Pi [cm] | Internal heigth Hi [cm] | Doorway L1xH1 [cm] | External width L [cm] | External depth P [cm] | External height H [cm] | Compressor power [hp] | Maximum absorbed power [kW] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ED 240 | 350 | 240 | 2 | 2 | 1 | 96 | 180 | 207 | 100×198 | 188 | 200 | 230 | 1×20 | 29 |

| ED 240 AL | 350 | 240 | 3 | 2 | 2 | 96 | 220 | 207 | 100×198 | 188 | 240 | 230 | 1×20 | 31 |

| ED 360 | 530 | 360 | 4 | 3 | 2 | 96 | 270 | 207 | 100×198 | 188 | 290 | 230 | 1×30 | 37 |

| ED 360 AL | 530 | 360 | 4 | 3 | 2 | 96 | 310 | 207 | 100×198 | 188 | 330 | 230 | 1×30 | 37 |

| ED 480 | 720 | 480 | 5 | 4 | 3 | 96 | 360 | 207 | 100×198 | 188 | 380 | 230 | 2×20 | 42 |

| ED 480 AL | 720 | 480 | 6 | 5 | 3 | 96 | 400 | 207 | 100×198 | 188 | 420 | 230 | 2×20 | 42 |

| ED 600 | 930 | 600 | 7 | 5 | 4 | 96 | 450 | 207 | 100×198 | 188 | 470 | 230 | 2×25 | 66 |

| ED 600 AL | 930 | 600 | 7 | 6 | 4 | 96 | 490 | 207 | 100×198 | 188 | 510 | 230 | 2×25 | 66 |

| ED 720 | 1070 | 720 | 8 | 6 | 5 | 96 | 540 | 207 | 100×198 | 188 | 560 | 230 | 2×30 | 76 |

| ED 720 AL | 1070 | 720 | 8 | 7 | 5 | 96 | 580 | 207 | 100×198 | 188 | 600 | 230 | 2×30 | 76 |

| ED 840 | 1400 | 840 | 9 | 7 | 6 | 96 | 630 | 207 | 100×198 | 188 | 650 | 230 | 2×40 | 87 |

| ED 840 AL | 1400 | 840 | 10 | 8 | 6 | 96 | 670 | 207 | 100×198 | 188 | 690 | 230 | 2×40 | 87 |

Scroll right >>>

(*) Data referred to 300 gr raw baguettes (diameter 3.5 cm - length 60 cm)

Technical features

- Adjustable temperature down to -40°C

- AISI 304 stainless steel internal finish

- White zinc-plasticized exterior finish

- Insulation thickness of 100 mm made of eco-friendly polyurethane

- Carriageable floor thickness 100 mm with internal finishing in AISI 304 stainless steel

- AISI 304 stainless steel access ramp

- Automatic hot gas defrosting

- Stainless steel feet for bottom aeration

- Electronic control with 7" touch screen graphic display

- Software SURG-TOUCH

- Stainless steel exterior

- AISI 304 Scotch Brite stainless steel front

- Water condensation

- Two-stage unit with the same cooling capacity

- Shipment with disassembled cabinet

- Tropicalized condenser

- Silenced and hooded unit

Our proofers are at your disposal!

You can come to our headquarter and try your recipes working with a laboratory 4.0!

Fill out the form, you will be contacted in no time!