Controlled fermentation

Biga (pre-fermented raw bread dough) is an ingredient often used in baking, and controlling its fermentation is critical to get a final product of the highest quality. By controlling the temperature it is possible to control and delay the fermentation process up to 72 hours, to obtain a perfectly fermented preparation ready to be used at the desired time.

Controlled fermentation advantages

Perfect dough

The raw bread dough ferments and is stored at controlled temperature, to obtain a final product of the highest quality, regardless of the different environment conditions or seasons

Less afternoon and weekend work

Going to the bakery to refresh the dough daily during afternoons or weekends is no longer needed

Efficiency and cost reduction

Thanks to the optimization of personnel use and the increased standardization of the productive process

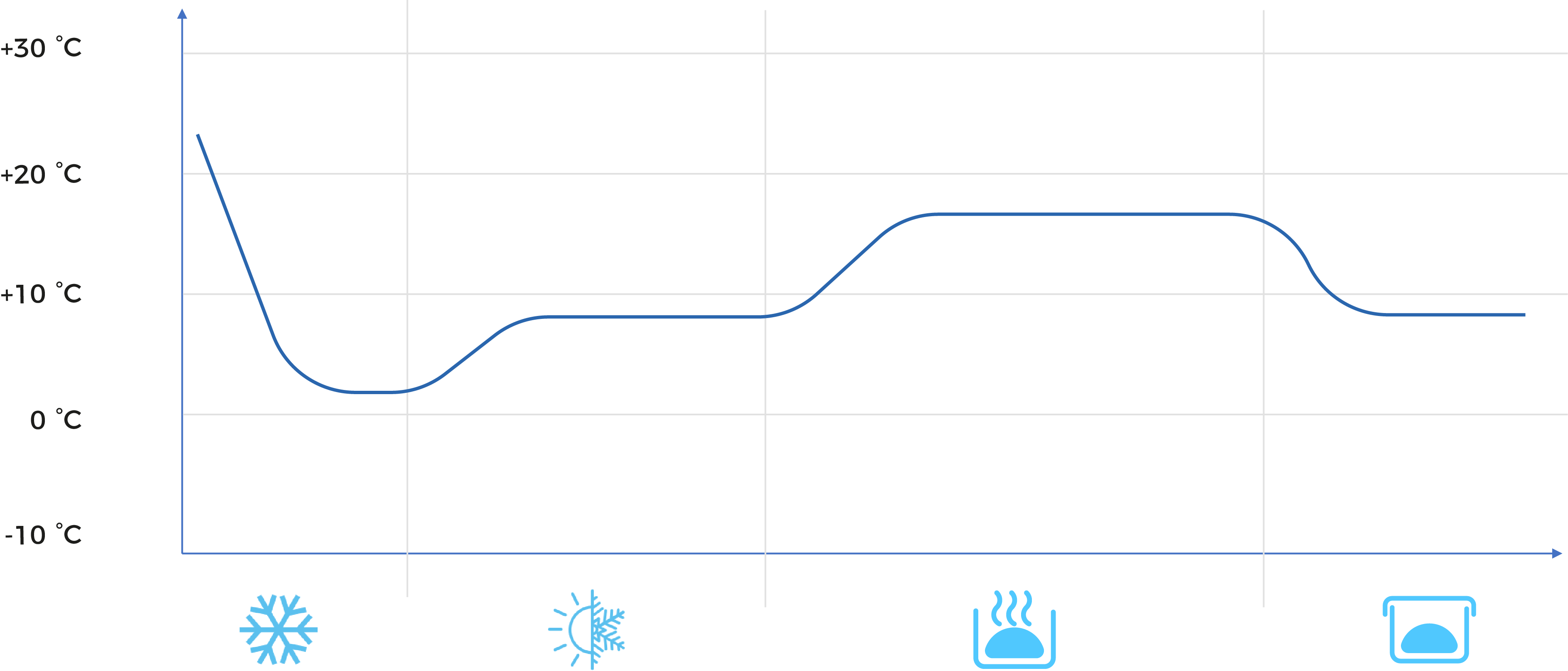

Controlled fermentation cycle

Thanks to its temperature management, the Controlled Fermentation cycle allows with its 3(+1) phases to delay and control the dough fermentation process, to have it fermented and ready for use at the desired time.

Cooling

The dough is cooled at low temperature, fermentation is blocked

Slowdown

Temperature remains low, fermentation is still suspended

Fermentation

The temperature slowly reaches the desired value, fermentation is resumed and completed

Fermentation block

Optional step to block the fermentation process once again by reducing the temperature, useful to keep the dough ready for use at a later time